Street Sweeper Lining Services

Industrial Screen & Maintenance offers street sweeper lining, repair, and replacement services for common wear parts found on street sweepers and other road maintenance equipment. For over 50 years, ISM has worked with clients across the globe on solving wear issues. With extensive urethane applications in the oil and gas industry, Industrial Screen & Maintenance is now applying that same proven technology to other industries including the road maintenance sector.

Benefits

Street sweeping equipment has many high wear parts. By lining or creating urethane OEM replacement parts with high wear resistance characteristics our clients are able to increase the life span of the part. Less time is spent replacing elbows, hoppers, drag shoes and more. With reduced maintenance, there is less downtime and reduced costs making your road maintenance operation run more efficiently. Plus, lined urethane parts make for an easier and more complete clean out of hoppers as urethane doesn’t allow for rusting to occur.

With two full CNC Machining, Welding, and Fabrication shops in Wyoming and Colorado, Industrial Screen & Maintenance is able to repair your equipment, remove old liners, reline, create new linings, manufacturing new OEM parts and get your equipment up and running faster than the competition saving you valuable downtime. Plus, we have quick led times and little to no cost tooling costs for creating prototypes for custom urethane parts for your road maintenance operation.

Street Sweeper Parts and Services

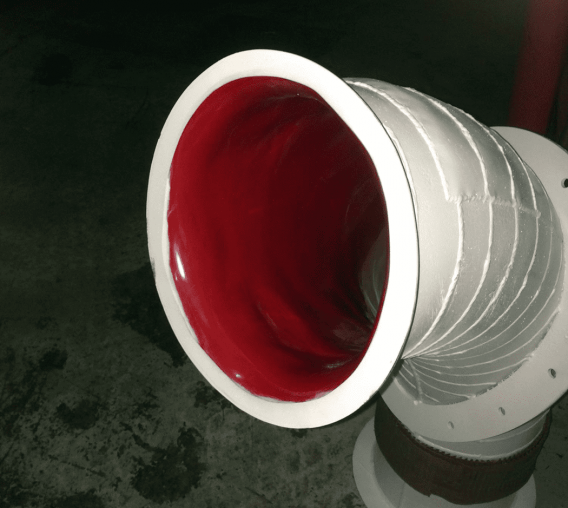

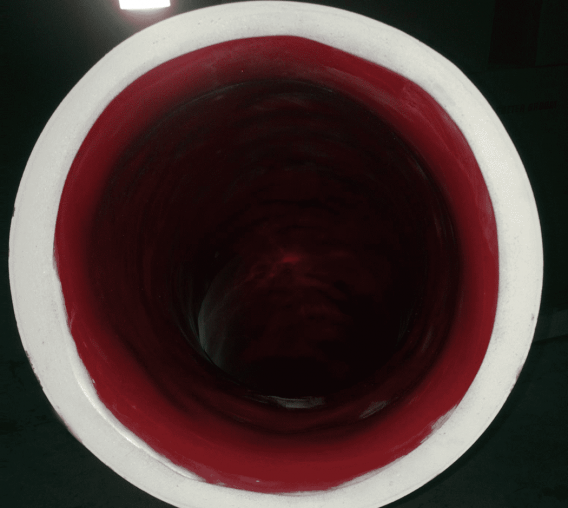

- Intake elbow manufacturing, repair & lining

- Pump repair and parts

- Sleeves manufacturing

- Drag shoe manufacturing

- Hopper lining

- Sprockets & idler manufacturing for elevator assembly

- Full machine shop services

- Welding and fabrication

- Product design and engineering

Lining Advantages

- Abrasion resistance

- Impact resistance allows debris to bounce off instead of impact metal components

- High tear strength

- Resistant to water, oil & grease

- High resiliency range

- Rust resistance

- Urethane can be bonded to various materials

- Performances is harsh environments and temperatures

- Urethane lining is more cost effective than part replacement

- Custom coloring

Polyurethane Material Advantages

| vs Plastic | vs Rubber | vs Metal |

| Impact and abrasion resistance | High tolerance to oil, oxygen and greases | More flexible and easier to mold |

| Elastomeric memory | Cut, tear, and high abrasion resistance | Quieter to operate |

| More durable and impact resistant | Wider hardness range | Abrasion resistance |

| Low temperature resistance | Ozone resistance | Lightweight & easily moldable |

| Radiation resistance | Radiation resistance | Corrosion resistance |

| Cold flow resistance | Castable | Impact resistant |

| Thick section molding | Colorability | Non-conductive |

Types of Cast Urethane Products

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

- AbrasionBlock

- Centralizers

- Urethane Covered Bearings

- Urethane Pads

- Chute Linings

- Wear Pads

- Urethane Heavy Duty Cast Iron Wheels

- Pump Impellers

Cast Urethane Product Specs

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Range of Shore Hardness

Shore 00

10,20,30,40,50,60,70

Shore A

10,20,30,40,50,60,70,80,90,95

Shore D

40,50,60,70,80

Why Work with ISM?

Made in the USA

Custom Quality Projects

Longevity Over 50 Years

Family Owned Business

Request A Quote

Industrial Screen and Maintenance is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires.