"The warehouse at WhiteStar is one of the cleanest and most organized warehouses I have ever been in. All the employees appear to be very well trained and the floors are kept very clean."

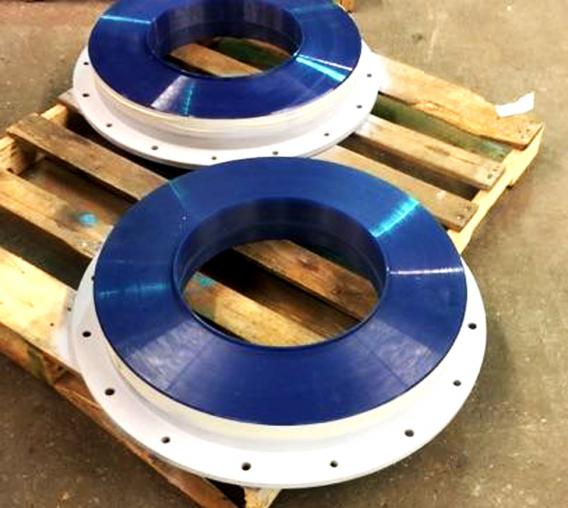

Abrasion Resistant Polyurethane Linings

Polyurethane liners, urethane coatings and urethane customized molds are produced from proprietary formulations and processing techniques. Urethane liners are often used when wear issues need to be solved and often save equipment from costly downtime and maintenance. The many outstanding physical properties of urethane along with its varied applications make it a material of choice.

Types Of Polyurethane Liners

ISM manufactures drop-in, bolt-in, magnetic, sheet and bonded cast polyurethane liners. Urethane can be bonded to a variety of materials to enhance the lifespan of manufactured parts and equipment.

Liners are often used for:

- Metal hoppers

- Chutes

- Grain bowls

- Discharges

- Bins

- Pipes and Fittings

- Trailers

- Road maintenance equipment

Cast lined are bonded for ultimate adhesion and protection. Bolt-in liners are perfect for protecting both small and large applications. This application allows for certain segments of the liner to be removed based upon wear allowing you to replace only sections that are needed. Magnetic Liners can be easily placed to aid in a variety of wear patterns. Large magnets hold panels in place giving your application a lot of flexibility. Sheet liners are a great option for customers looking to create a liner on-site to specific dimensions and needs. We can also create sheets in specific shapes too.

Benefits

-

Abrasion & Tear Resistant

-

Chemical and Corrosion Resistant

-

Temperature Resistance – It does not get brittle in colder temperatures.

-

Impact Resistant

-

Adhesion – Bonds easily to other materials.

-

Coloring – ISM can customize a color for your application.

-

Versatile – Can be used in a variety of options

-

Friction Coefficients

-

Sound Damping Properties

-

Shock Absorptions

-

High Load Bearing Capacity

-

Ozone & Ultraviolet Resistant

-

Machinability

Common Applications for the Advanced Polyurethane Liners

Contact UsOur advanced polyurethane liners provide protection against breakdown caused by chemicals and solids. We commonly line pipes with urethane for the following industries:

- Mining industry

- Automobile industry

- Oil & gas industry

- Fracking industry

Our urethane linings are designed with customized formulations to provide maximum protection in your particular application. We add our AbraisonBlock lining to a wide variety of products for these industries including:

- Liners for components

- Automobile components

- Oil & gas industry

Abrasion Resistant Linings

Customized Cast Urethane

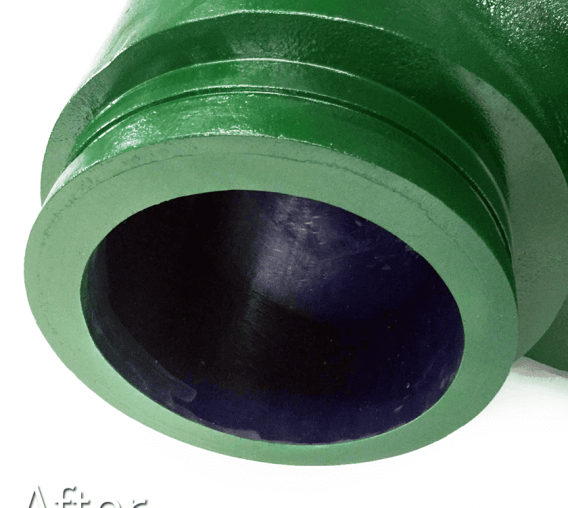

Our in-house machine shop allows us to easily manufacture a cast mold to meet your specific liner needs. Cast urethane is economical as there is little to no tooling costs. Our facility can handle both small and large production runs to meet your needs. Plus, we can handle the stripping of old polyurethane liners which will save your operation time and money. After the stripping process, our machinists are able to repair parts and materials needing a bonded urethane liner.

What's The Difference Between A Cast Urethane Liner And A Spray-In Liner

At ISM, all of our liners are cast urethane liners. We do not manufacture urethane spray-in liners. Many people think cast urethane liners and spray-in liners have comparable characteristics and durability. However, this is simply not the case. Cast urethane liners are much thicker than spray-in liners, often ranging in thickness from ¼” to 1”. All of our cast urethane is custom-made to fit our client’s application and design needs. Plus, cast urethane is cured in a high-temperature oven ensuring its high performance and amazing durability. Simply put, cast urethane liners far exceed the wear life of spray-in liners.

Polyurethane Material Advantages

| vs Plastic | vs Rubber | vs Metal |

| Impact and abrasion resistance | High tolerance to oil, oxygen and greases | More flexible and easier to mold |

| Elastomeric memory | Cut, tear, and high abrasion resistance | Quieter to operate |

| More durable and impact resistant | Wider hardness range | Abrasion resistance |

| Low temperature resistance | Ozone resistance | Lightweight & easily moldable |

| Radiation resistance | Radiation resistance | Corrosion resistance |

| Cold flow resistance | Castable | Impact resistant |

| Thick section molding | Colorability | Non-conductive |

Types of Cast Urethane Products

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

- AbrasionBlock

- Centralizers

- Urethane Covered Bearings

- Urethane Pads

- Chute Linings

- Wear Pads

- Urethane Heavy Duty Cast Iron Wheels

- Pump Impellers

Cast Urethane Product Specs

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Range of Shore Hardness

Shore 00

10,20,30,40,50,60,70

Shore A

10,20,30,40,50,60,70,80,90,95

Shore D

40,50,60,70,80

Why Work with ISM?

Made in the USA

Custom Quality Projects

Longevity Over 50 Years

Family Owned Business

What our Clients are Saying

Contact Us

Industrial Screen and Maintenance is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires.