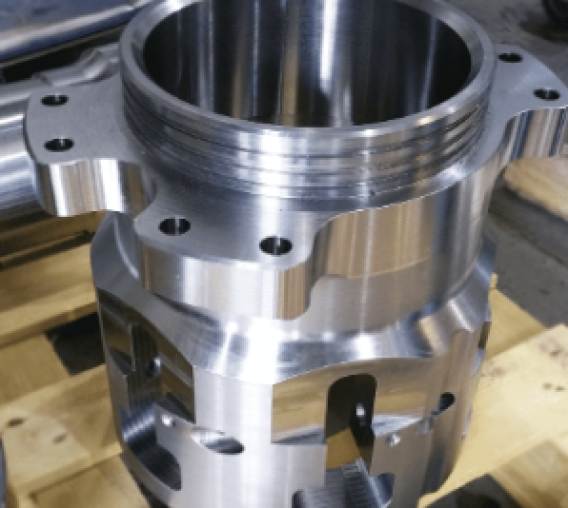

CNC Lathe Milling Services

Source the custom components you need with CNC turning service solutions by Industrial Screen and Maintenance. In addition to our extensive line of wire cloth and mesh, we offer CNC lathe and milling services for custom solutions. Explore our services and reach out when you’re ready to receive custom, made-in-the-USA components.

Our CNC Machining Service Benefits

Choose our CNC milling service or lathe service to customize your components. Select the material and design you need to fit your industry specifications and we’ll provide quality components built to exceed your standards. Here are the benefits you can receive when working with our team:

- Quick lead times

- Made-in-America quality

- Proprietary lining

Our team will describe the alloy options, weave types, and other specifications to ensure you receive a quality product that meets your component needs. Explore the differences between CNC milling and lathe services to learn which in-house option we can use to tailor your materials to your next project.

Your Turn-Key CNC Turning Service Provider

While both CNC machining options offer custom components to meet your specifications, there are distinct differences between CNC turning and CNC lathe. A CNC lathe service, also known as turning, has both horizontal and vertical orientations. Once the workpiece material is selected and fitted into the machine, it spins and is brought into contact with the lathe tool.

Our modern CNC lathes turn at exceptional speeds to provide fast, efficient production of custom components. After designing the product and setting up the workpiece, the lathe quickly creates your chosen design. Whether turning one workpiece or handling a large order, discuss your needs with our in-house team to see how we can accommodate your needs.

How Our CNC Milling Service Compares

Another key CNC machining service we provide at Industrial Screen and Maintenance is CNC milling. These machines are also available in both horizontal and vertical orientations for tailored cutting solutions. A CNC mill secures your workpiece to a table with a stationary cutting tool ready to make contact. The table is then moved to make the precision cuts necessary to follow your CNC designs.

Contact Us To Learn More About CNC Solutions

At Industrial Screen and Maintenance, we’re committed to offering quality components and quick lead times. Contact us today to hear more about our CNC milling and CNC turning service options. We’re confident we can assist you with crafting the quality workpieces you need to move forward in your industry.