Urethane Pump Impeller Applications

When it comes to upgrading your troublesome pump parts, Industrial Screen is full service from start to finish including intricate mold design and manufacturing, precise metering and mixing equipment and step by step quality control to meet and exceed industry standards. Our complete services include repair and relining services that include stripping of old linings, steel repair for warn wear plates, fittings, elbows, tubs, fan housings and mixers.

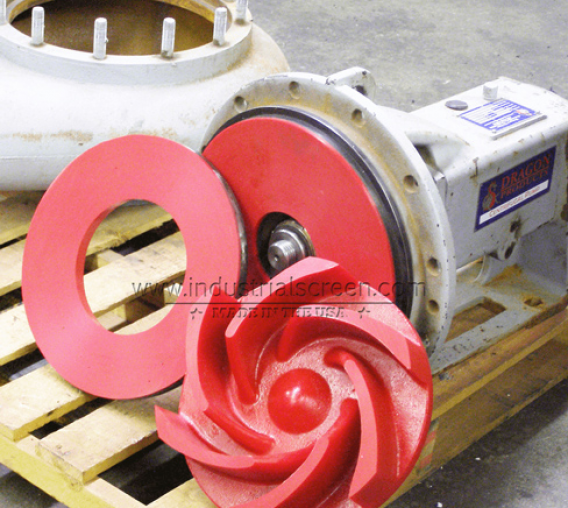

Urethane Pump Impellers

When it comes to high wear urethane pump impellers and slurry pump parts, Industrial Screen has over 50 years of experience with industrial grade polyurethane replacing rubber and alloy parts. Urethane is an excellent material for abrasion and corrosion resistant properties for fine abrasive slurries. Many of our global clients rely on Industrial Screen to provide ultimate protection with our cast bonded linings and cast molded urethane products to fit their OEM Pumps in power plants, mining operations and fracking equipment.

Benefits

Industrial Screen’s proprietary formulations and processing techniques are designed for exceptional wear in fine feed environments greatly increasing the components wear life, giving you years of trouble free service.

Parts

- Urethane Bar Stock

- Urethane Flat Stock

- Hydroclones

- Mixers and Tubs

- Elbows, Pipe Spools and Pipe Fittings

- Fan Intake Housings

- Gaskets, Wedges and Spacers

- Pump Impellers and Pump Parts

- Pump flingers and slingers

- Screens of all shapes and sizes

- Suction Liners

- Wear Plates

- Wheels

Utilizing our in-house engineering team

CNC Lathes and Mills we are able to produce the highest quality molds much faster than any of our competitors. With our dedicated team and decades of experience we can ensure the perfect fit and finish for even the most intricate designs. With our expansive inventory of patterns and molds in stock to fit many OEM parts on the market today.

Polyurethane Material Advantages

| vs Plastic | vs Rubber | vs Metal |

| Impact and abrasion resistance | High tolerance to oil, oxygen and greases | More flexible and easier to mold |

| Elastomeric memory | Cut, tear, and high abrasion resistance | Quieter to operate |

| More durable and impact resistant | Wider hardness range | Abrasion resistance |

| Low temperature resistance | Ozone resistance | Lightweight & easily moldable |

| Radiation resistance | Radiation resistance | Corrosion resistance |

| Cold flow resistance | Castable | Impact resistant |

| Thick section molding | Colorability | Non-conductive |

Types of Cast Urethane Products

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

- AbrasionBlock

- Centralizers

- Urethane Covered Bearings

- Urethane Pads

- Chute Linings

- Wear Pads

- Urethane Heavy Duty Cast Iron Wheels

- Pump Impellers

Cast Urethane Product Specs

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Range of Shore Hardness

Shore 00

10,20,30,40,50,60,70

Shore A

10,20,30,40,50,60,70,80,90,95

Shore D

40,50,60,70,80

Why Work with ISM?

Made in the USA

Custom Quality Projects

Longevity Over 50 Years

Family Owned Business

Request A Quote

Industrial Screen and Maintenance is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires.