Uses for Cast Urethane Sheets

Cast urethane sheet is an economical way to manufacture high-performing products. It’s a great material for rings, gaskets, squeegees, and vibration dampening pads. Other applications include:

- Pipe Drifts

- Pipe Pigs

- Elbow Linings

- Flapper Doors

- Chute Liners

- Sleeves

- Press Brake Pads

- Vibration Isolators

- Bumper Pads

- Covered Bearings

- Belt Scrappers

- Conveyor Line Skirting

Polyurethane Sheet Stock

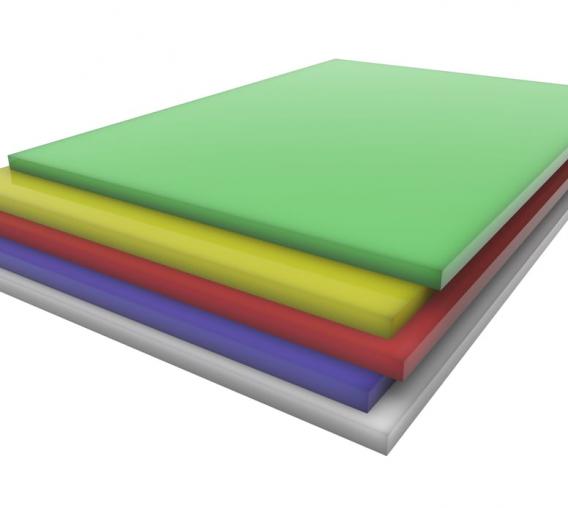

Industrial Screen & Maintenance is a leading provider of polyurethane sheet stock, a versatile compound used to manufacture products that stand up to abrasion and wear . We can supply cast urethane sheets in various sizes, thicknesses, hardnesses, and colors to meet your requirements.

The ISM Advantage

Industrial Screen & Maintenance has developed proprietary urethane blends proven to be more resilient, versatile, and durable than other plastics, rubber, and steel. Additional benefits include:

- High Abrasion Resistance

- High Tear Strength

- High Solvent, Fuel & Oil Resistance

- High Dry Heat Resistance Up To 225 Degrees Fahrenheit

- High Corrosion Resistance

- Available In Any Color

Polyurethane Sheet Stock Hardness

Urethane sheet is available in many hardnesses. Here’s our shore hardness availability:

Shore 00: 10, 20, 30, 40, 50, 60, 70

Shore A: 10, 20, 30, 40, 50, 60, 70, 80, 90, 95

Shore D: 40, 50, 60, 70, 80

Custom formulations are available upon request.

Applications

- CNC Machining

- Manual Machining

- Welding

- Urethane Mold Design

- Urethane Mold Manufacturing

- Steel Core Urethane Products

- Urethane Rollers

Let Us Handle Manufacturing

If you’re looking to turn urethane sheet into finished products, Industrial Screen & Maintenance is here to help. We offer a full suite of manufacturing services at our facilities in Casper, Wyoming, and Grand Junction, Colorado.

With a leading polyurethane sheet stock, we can make cast urethane products using your print, specification, or purchase order requirements quickly and affordably. Those with an idea but no vetted design are welcome, too.

Our engineering team can help you develop a concept and design a prototype. Upon acceptance, full-scale production kicks off.

Polyurethane Material Advantages

| vs Plastic | vs Rubber | vs Metal |

| Impact and abrasion resistance | High tolerance to oil, oxygen and greases | More flexible and easier to mold |

| Elastomeric memory | Cut, tear, and high abrasion resistance | Quieter to operate |

| More durable and impact resistant | Wider hardness range | Abrasion resistance |

| Low temperature resistance | Ozone resistance | Lightweight & easily moldable |

| Radiation resistance | Radiation resistance | Corrosion resistance |

| Cold flow resistance | Castable | Impact resistant |

| Thick section molding | Colorability | Non-conductive |

Types of Cast Urethane Products

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

- AbrasionBlock

- Centralizers

- Urethane Covered Bearings

- Urethane Pads

- Chute Linings

- Wear Pads

- Urethane Heavy Duty Cast Iron Wheels

- Pump Impellers

Cast Urethane Product Specs

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Range of Shore Hardness

Shore 00

10,20,30,40,50,60,70

Shore A

10,20,30,40,50,60,70,80,90,95

Shore D

40,50,60,70,80

Contact Us Today

Industrial Screen and Maintenance is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires.