Custom Polyurethane Capabilities

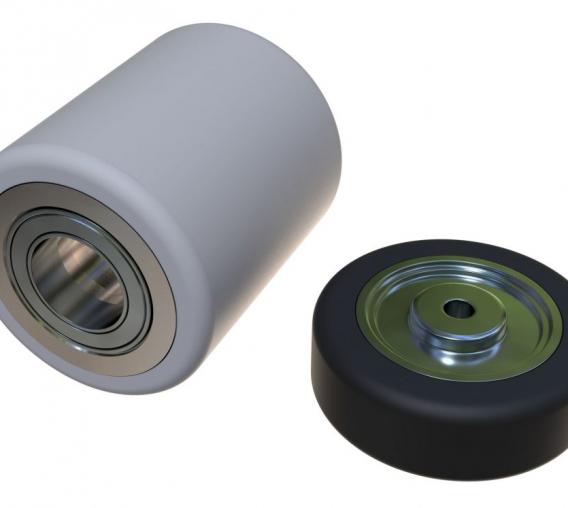

Additionally, we manufacture urethane wheels, heavy-duty caster wheels, pulleys, and shafts with bearings.

Mounting options include bearing mount, threaded stud mount, and shaft mount.

With specialized CNC machinery, our machinist can create many different roller profiles including straight, convex, concave, tapered ends, double tapered, and full tapered. Additionally, groove patterns can include threading, chevron, ruling, right-hand grove, spreader, diamond, spiral, herringbone and step, and plunge.

Custom Polyurethane Rollers & Wheels

Polyurethane Rollers and Guide Wheels made to your specifications on demand with rapid shipping.

With clients across the globe, Industrial Screen & Maintenance (ISM) has designed and engineered numerous custom urethane products for a variety of applications across several different industries. With over 50 years of experience, ISM is a leader in manufacturing urethane rollers, wheels, pulleys, and bearings with a tight tolerance of +/-.005. Our proprietary urethane blends allow for the industry’s largest range of hardness on the Durometer Shore Hardness Scale ranging from Shore 00 to Shore D 80

Applications

Urethane possesses several attractive properties for rollers, wheels, pulleys and bearings including high load bearing capacity, flexibility, strong bonding properties, high tensile strength, shock absorbency, beneficial electrical properties, and tear, abrasion, impact, chemical, water, oil, grease, mold, mildew and fungus resistance. Additionally, urethane is an economical manufacturing application. At ISM, we are able to not only manufacture the urethane; we manufacture the cast molds making the production of urethane components even more economical for our customers.

Types of Polyurethane Rollers

We can bond urethane rollers to steel, aluminum, and fiberglass in complex shapes for your unique application. Here is a list of roller types we can manufacture:

- Step and Plunge Rollers

- Flat Taper Rollers

- Chevron Rollers

- Multiple Crown Rollers

- Hourglass Rollers

- Conveyor Rollers

- Drive Rollers/Wheels

- V-Rollers

- Nip Rollers

- Idler Rollers

- Feed Rollers

- Wringer Rollers

- Custom Shaped Urethane Rollers

- Pinch Rollers

- Keyed Polyurethane Drive Rollers

- Convex Rollers

- Profile Ground Rollers

- Tapered Rollers

- Slip On Rollers

- Coated Sleeve Rollers

- Straight Roller

- Cell Rollers

- Hold down Roller

- AGV Stacker

- Guide Rollers with or without industrial grade bearings

Polyurethane Material Advantages

| vs Plastic | vs Rubber | vs Metal |

| Impact and abrasion resistance | High tolerance to oil, oxygen and greases | More flexible and easier to mold |

| Elastomeric memory | Cut, tear, and high abrasion resistance | Quieter to operate |

| More durable and impact resistant | Wider hardness range | Abrasion resistance |

| Low temperature resistance | Ozone resistance | Lightweight & easily moldable |

| Radiation resistance | Radiation resistance | Corrosion resistance |

| Cold flow resistance | Castable | Impact resistant |

| Thick section molding | Colorability | Non-conductive |

Types of Cast Urethane Products

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

- AbrasionBlock

- Centralizers

- Urethane Covered Bearings

- Urethane Pads

- Chute Linings

- Wear Pads

- Urethane Heavy Duty Cast Iron Wheels

- Pump Impellers

Cast Urethane Product Specs

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Range of Shore Hardness

Shore 00

10,20,30,40,50,60,70

Shore A

10,20,30,40,50,60,70,80,90,95

Shore D

40,50,60,70,80

Why Work with ISM?

Made in the USA

Custom Quality Projects

Longevity Over 50 Years

Family Owned Business

Request A Quote

Industrial Screen and Maintenance is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires.