Custom Cast Polyurethane Products

Industrial Screen & Maintenance (ISM) has been providing Cast Polyurethane Products and Casted Polyurethane Linings for over 50 years. Working with clients across the globe in various industries whom all share similar problems of abrasion leading to part failure. ISM understands wear and tear in highly abrasive environments, chemical corrosion, and damage from debris. Cast Urethane is a versatile and cost-effective solution. It can be applied in a variety of ways to new and old equipment, preventing costly downtime.

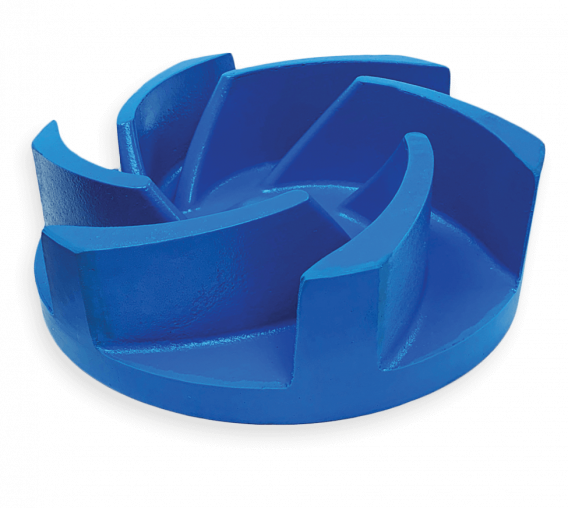

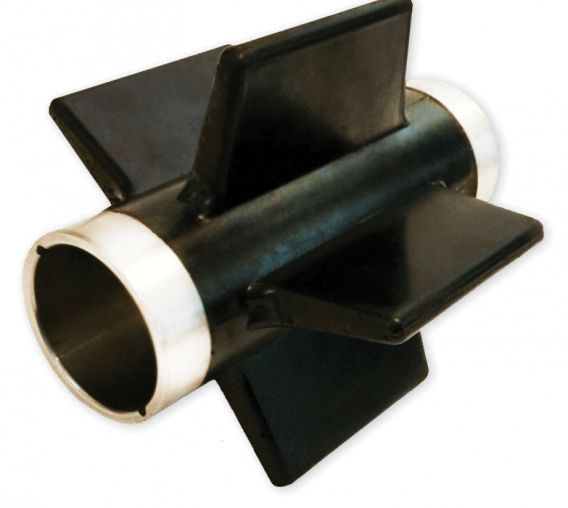

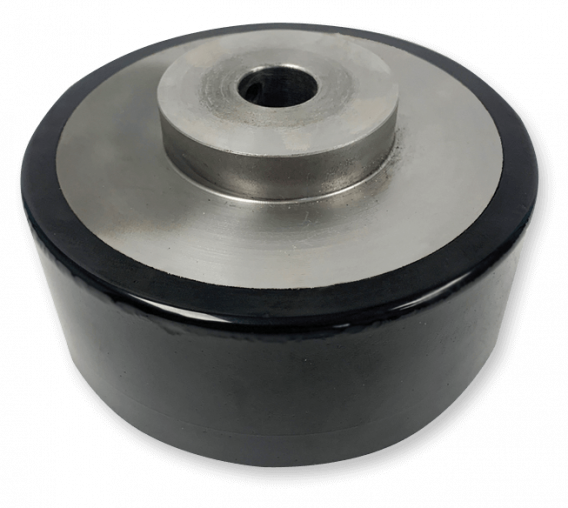

ISM’s proprietary Urethane blends make for a stronger, more versatile, and more durable product proven to outlast other plastics, rubber, and steel. Custom-cast polyurethane products can be designed for superior abrasion resistance and stand up to even the most corrosive chemicals without cracking, tearing, swelling, or deteriorating. Proven wear life of up to 10x to common alloy steel in some applications.

Quality cast polyurethane products from Industrial Screen save you valuable time and money, greatly reducing your part replacement costs.

Custom Cast Polyurethane Capabilities

- Full Machine Shop Services

- In-house Mold Design and Manufacturing

- Durometers from 25 Shore 00 to 70 Shore D

- Ability to repair and re-cast existing equipment

- Complete In-house Metal Repair and Machining Services

- Quality Casted Urethane Since 1969

Cast Urethane Product Benefits

- High Abrasion Resistance

- High Tear Strength

- High Solvent, Fuel & Oil Resistance

- High Dry Heat Resistance up to 225F

- High Corrosion Resistance

- Available in Any Color

- Customized Formulations to provide the maximum protection possible

- Suitable for all industries and applications; Mining, Oil and Gas, Road Equipment, Water Treatment, Process, and Sand and Gravel.

Polyurethane Material Advantages

| vs Plastic | vs Rubber | vs Metal |

| Impact and abrasion resistance | High tolerance to oil, oxygen and greases | More flexible and easier to mold |

| Elastomeric memory | Cut, tear, and high abrasion resistance | Quieter to operate |

| More durable and impact resistant | Wider hardness range | Abrasion resistance |

| Low temperature resistance | Ozone resistance | Lightweight & easily moldable |

| Radiation resistance | Radiation resistance | Corrosion resistance |

| Cold flow resistance | Castable | Impact resistant |

| Thick section molding | Colorability | Non-conductive |

Types of Urethane Molded Products

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

- AbrasionBlock

- Centralizers

- Urethane Covered Bearings

- Urethane Pads

- Chute Linings

- Wear Pads

- Urethane Heavy Duty Cast Iron Wheels

- Pump Impellers

Cast Urethane Product Specs

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Range of Shore Hardness

Shore 00

10,20,30,40,50,60,70

Shore A

10,20,30,40,50,60,70,80,90,95

Shore D

40,50,60,70,80

Why Work with ISM?

Made in the USA

Custom Quality Projects

Longevity Over 50 Years

Family Owned Business

Why Work with ISM?

Industrial Screen & Maintenance has been serving custom urethane solutions to clients globally for over 50 years in various industries. Watch this video to learn more about our custom polyurethane capabilities and the common industries we serve:

food processing, metal forming, military, die cutting, fluid cell remold, OEM’s, Marine, process automation, aerospace, sanitation, box board manufacturing, woodworking, flexible packaging, plastics industries, metal, blown film, breweries, printing, glass, textile, and many others.

Contact Us

Industrial Screen and Maintenance is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires.