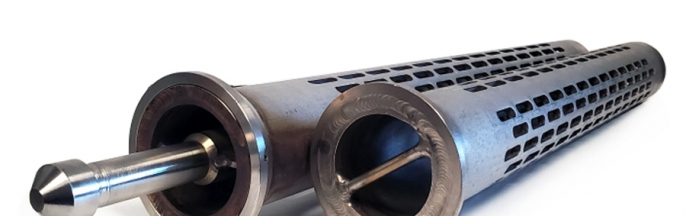

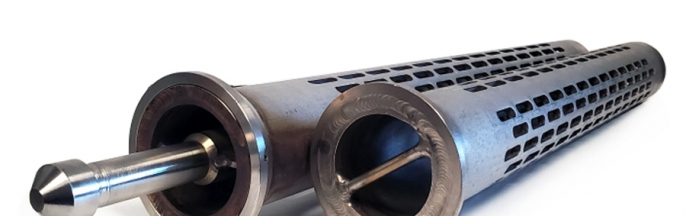

Drill Pipe Screens and Strainers are a vital component in any directional drilling application, protecting valuable equipment from highly abrasive solids.

Your browser is out of date.

You are currently using Internet Explorer 7/8/9, which is not supported by our site. For the best experience, please use one of the latest browsers.

Industrial Screen’s Patented Urethane Pipe Drifts and Casing Drifts are designed to outlast all other drifts on the market including; steel, Teflon and even chrome-plated drifts. Casing Drifts and Tubing Drifts are used for testing the roundness of Tubing and Casing; verifying there are no dents, bends or flat areas that would prevent downhole tooling from passing through. Our Urethane Tubular Drifts are manufactured to API 5CT Specifications or your custom specifications. Custom Rabbit’s can be built to match the size and length of a particular tool to verify it will pass without getting hung up costing drilling operator’s expensive downtime.

Valve drifts are available as well. Made to meet API 6A and API 16A for valves, Christmas trees or any custom configuration. Large in-stock variety of all common API Tubing Drifts, Pipe Drifts and Casing drifts made to API 5CT Specifications are available for immediate shipment.

Our patented design is made from high-quality 95A abrasion-resistant urethane, with a steel core and pull-through handle. They are designed to absorb impact and protect the tubular by preventing any unwanted scratching of your coated pipe. Our Urethane Pipe Drifts are lightweight, weighing much less than our competitor’s heavy steel versions. Due to the lighter weight, inspectors can use them with a vacuum-powered pull through, compressed air or rope pull through. Industrial Screen’s proprietary blend of Urethane makes for a wear and corrosion resistant Tubing Drift that will outlast even our Teflon Competitors at a third of the cost.

Industrial Screen has been manufacturing quality oilfield products since 1969. As a full service, Machine Shop and CNC Manufacturing facility with onsite engineers we have a unique and unmatched ability to design and manufacture.

Drill Pipe Screens and Strainers are a vital component in any directional drilling application, protecting valuable equipment from highly abrasive solids.

Bonded to metal to provide additional stiffness and installation advantages.

Custom cast polyurethane products can be designed for superior abrasion resistance and stand up to even the most corrosive chemicals.

Industrial Screen’s Solid Cast Urethane Pipeline Pig is ideal for scrapping, sealing and long-lasting pipe cleaning

We manufacture urethane wheels, heavy-duty caster wheels, pulleys, and shafts with bearings.

| vs Plastic | vs Rubber | vs Metal |

| Impact and abrasion resistance | High tolerance to oil, oxygen and greases | More flexible and easier to mold |

| Elastomeric memory | Cut, tear, and high abrasion resistance | Quieter to operate |

| More durable and impact resistant | Wider hardness range | Abrasion resistance |

| Low temperature resistance | Ozone resistance | Lightweight & easily moldable |

| Radiation resistance | Radiation resistance | Corrosion resistance |

| Cold flow resistance | Castable | Impact resistant |

| Thick section molding | Colorability | Non-conductive |

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Range of Shore Hardness

Shore 00

10,20,30,40,50,60,70

Shore A

10,20,30,40,50,60,70,80,90,95

Shore D

40,50,60,70,80

Industrial Screen and Maintenance is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires.

Thank you for your interest in Industrial Screen & Maintenance. We will get back to you shortly!

750 East F Street

Casper, WY 82601

307 234 3547

2285 Logos Court

Grand Junction, CO 81505

970 245 4020