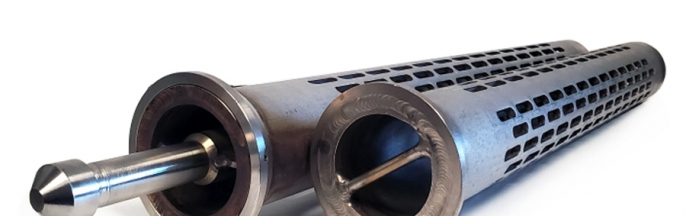

Cone Strainers

Temporary Cone Strainers, or Conical are used in a variety of pipeline applications for gas, oil, steam, and water.

Click here to learn moreYour browser is out of date.

You are currently using Internet Explorer 7/8/9, which is not supported by our site. For the best experience, please use one of the latest browsers.

ISM is an industry leader in Industrial Screen manufacturing and has been providing all types of Oil and Gas screens for over 50 years. ISM has designed and supplied many varieties of drilling, pumping, filtering, sorting, sifting, and processing screens used throughout all drilling, production, fracking and refining operations. We carry a large in stock inventory of screen materials including ready to ship drill pipe screens in common API connections

Oil and Gas Industry relies heavily on threaded connections, these critical connections require inspection, and services to keep them running smoothly. ISM Machinists are fully trained in all shouldered connection including API, as well as casing and tubing connections. Two locations with full-service Tubular Repair Services in Casper, Wyoming and Grand Junction, Colorado. ISM is an Oil & Gas industrial screen manufacturer with a team full of experienced machinists, welders, and fabricators ready to help repair or replace your broken damaged equipment.

The Oil and Gas Industry is crucial to the world’s economic framework and is one of the largest sectors in the world for revenue generation. Oil and gas production is also one of the most capital-intensive industries, requiring expensive equipment and highly skilled labors. Oil and Gas Industry can be broken down into three segments: upstream, midstream, and downstream. Industrial Screen and Maintenance (ISM) has worked with all three sectors over the years creating oil & gas urethane parts to help provide solutions for the many challenges in the industry.

ISM Cast Urethane liners have revolutionized the Fracking industry, by developing a proprietary polyurethane lining application specifically for hydraulic fracturing operations. The Hydraulic Fracking operators face nonstop abrasion from solids, sand, and chemical corrosion. The Abrasionblock Urethane liners have been applied on blender tubs, manifolds, elbows, flanges, and other fittings for many of the large fracking operators for decades, shipping them around the globe. Our team of highly qualified Urethane Technicians can burn out old liners, repair worn-out steel surfaces, prep, and re-line with new Polyurethane. This liner lasts up to 10x longer than standard steel tubs.

Temporary Cone Strainers, or Conical are used in a variety of pipeline applications for gas, oil, steam, and water.

Click here to learn more

Designed to absorb impact and protect the tubular by preventing any unwanted scratching of your coated pipe.

Click here to learn more

Made from quality 304 Stainless Perforated Steel, they are guaranteed to outlast all competitor bird screens on the market today.

Click here to learn more

Vital component in any directional drilling application, protecting valuable equipment from highly abrasive solids.

Click here to learn more

Our polyurethane liners and urethane coatings & linings are custom manufactured to solve wear issues related to bulk transport of a variety of materials.

Click here to learn more

Our stabbing guides provide durability taking abrasion and hard blows with shock-absorbing capabilities time and time again.

Click here to learn moreOur team of highly qualified Urethane Technicians can burn out old liners, repair the worn-out steel surfaces, prep, and re-line with new Polyurethane. This liner lasts up to 10x longer than standard steel tubs.

Thank you for your interest in Industrial Screen & Maintenance. We will get back to you shortly!

750 East F Street

Casper, WY 82601

307 234 3547

2285 Logos Court

Grand Junction, CO 81505

970 245 4020