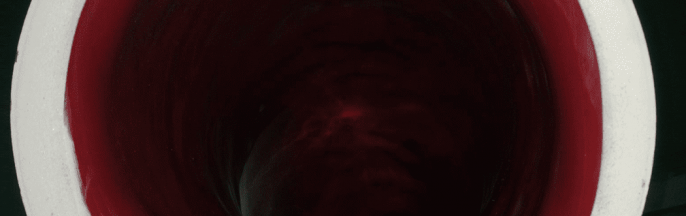

Urethane Lined Pipe

Our polyurethane lined pipe and fittings are custom manufactured to solve your abrasion issues. Order today!

Click here to learn moreYour browser is out of date.

You are currently using Internet Explorer 7/8/9, which is not supported by our site. For the best experience, please use one of the latest browsers.

When you’re on-site during the fracking process your equipment experiences extreme abrasion and wear. Because of the importance of the materials at play, the last thing you want to worry about is the integrity of your pumping equipment. Downtime and replacement costs can be incredibly expensive. Increasing your equipment’s life is critical to your operational success

Fortunately, with ABRASIONBLOCK from Industrial Screen and Maintenance, your equipment will be well-equipped to handle the task at hand and will outlast all standard equipment up to 10 times. Customers have reported being able to go through 75-100 tons of sand prior to requiring a reline. Our ABRASIONBLOCK Polyurethane Lining is the perfect material for an added layer of protection to all the high wear components used in the fracking process.

Including:

• Lining of blender tubs includes repair and reline of existing tubs

• Lining of blender tub wear plates

• Lining of fracking truck pump inlets and outlets

• Lining of all fittings and flanges used in the fracking operations

We have over 50 years of experience with Polyurethane blends, and our proprietary formulations and processing techniques create the best abrasion and chemical protection in the industry.

Our Polyurethane Liners, Polyurethane Coatings, and Polyurethane Customized Molded Products ensure your fracking procedures are completed with highly secure and safe equipment.

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Our polyurethane lined pipe and fittings are custom manufactured to solve your abrasion issues. Order today!

Click here to learn more

Polyurethane liners, urethane coatings and urethane customized molds are produced from proprietary formulations and processing techniques.

Click here to learn more

ISM offers full repair, replacement and lining services for common wear parts found on street sweepers and other road maintenance equipment.

Click here to learn more| vs Plastic | vs Rubber | vs Metal |

| Impact and abrasion resistance | High tolerance to oil, oxygen and greases | More flexible and easier to mold |

| Elastomeric memory | Cut, tear, and high abrasion resistance | Quieter to operate |

| More durable and impact resistant | Wider hardness range | Abrasion resistance |

| Low temperature resistance | Ozone resistance | Lightweight & easily moldable |

| Radiation resistance | Radiation resistance | Corrosion resistance |

| Cold flow resistance | Castable | Impact resistant |

| Thick section molding | Colorability | Non-conductive |

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

A urethane molded product is a custom product designed for applications that require abrasion resistance and durable material. Our proprietary urethane blends make for a stronger and more versatile product to outlast metal, rubber, and plastic.

Range of Shore Hardness

Shore 00

10,20,30,40,50,60,70

Shore A

10,20,30,40,50,60,70,80,90,95

Shore D

40,50,60,70,80

When you need your new or existing fracking equipment lined with the highest quality product on the market, you need ABRASIONBLOCK by Industrial Screen and Maintenance. Our line of Polyurethane Liners, Polyurethane Coatings, and Polyurethane Customized Molds can help you save time and money by providing optimal strength and protection for fracking tub liners during the fracking process. It will be the most cost-effective purchase you can make to ensure the safety of your crew and the success of your operation.

Industrial Screen and Maintenance is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires.

Thank you for your interest in Industrial Screen & Maintenance. We will get back to you shortly!

750 East F Street

Casper, WY 82601

307 234 3547

2285 Logos Court

Grand Junction, CO 81505

970 245 4020